Taking the smart approach to door security

Over 50% of homes in Britain now contain a smart device, that’s over 2.2 million households*. Here Sumier Foster-Shah, Product Support Manager at ERA, explores the latest advancements in smart home security and the opportunities these present for installers

As homeowners look to automate their lives and make their daily routines more convenient and efficient, the demand for smart devices is continuing to grow at a rapid rate, whilst advancements in connected technology are also accelerating. This presents installers with the opportunity to meet customer demand and differentiate themselves from competitors by partnering with door manufacturers who are adopting a proactive approach to smart security.

By installing entrance doors that have been fabricated with the very latest advancements in smart technology, professionals can ensure they remain ahead of the connected curve and secure potential cross-selling opportunities with complementary home security ecosystems.

This includes systems such as ERA’s new door security solution, TouchKey, which provides multi-factor authentication for residential door access.

The only system of its kind to combine five different entry methods into a single door handle, TouchKey facilitates the unlocking of the door via fingerprint access, the ERA Smart Home app, geolocation technology and voice-activated entry. For ultimate peace of mind, TouchKey also contains a hidden manual key override, with three keys supplied as standard.

Featuring advanced fingerprint technology, up to 50 different fingerprints can be stored directly within the handle to provide users with instant access to the property.

When used with the ERA Smart Home app, TouchKey can be unlocked with a single touch locally or remotely via the addition of an ERA alarm hub. Digital e-keys that have timed access can also be assigned to individuals, such as family and friends, via the app. Voice command can be utilised via the app to unlock the door on approach, without having to physically touch a smartphone.

With geolocation technology, the system can remotely unlock via Bluetooth as a trusted digital e-key grants access to the individual once they are within range of the property, without needing to physically use their smartphone.

Suitable for fabrication with composite or timber entrance doors, TouchKey combines a smarter security door handle with an auto-firing multi-point lock and an anti-bump security cylinder.

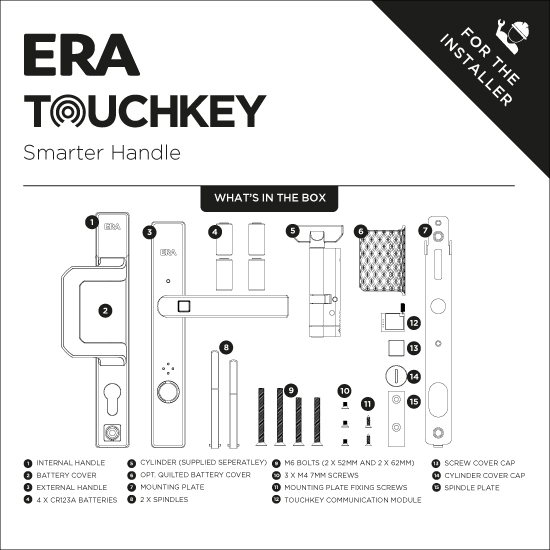

Whilst the multi-point lock and anti-bump security cylinder will be fitted at the point of fabrication, the battery-powered handle can easily be fitted on-site using M6 security screws by professional installers, without the requirement for electrical qualifications. The only difference from fitting a standard door handle is the connection of a single wire from one side of the handle to the other.

Because TouchKey integrates with the wider ERA Protect smart ecosystem, installers can also achieve cross-selling opportunities by recommending and fitting complementary security products that can be conveniently stored in the back of a van until they are required. This includes products such as alarm systems and outdoor cameras, which provide real-time monitoring via an app, whilst also acting as an effective visual deterrent for potential burglars.

Whilst the smarter handle is built for endurance and security due to the addition of a forged steel backplate and hardened plates that prevent potential attackers from removing the handle to access the lock, it also delivers on aesthetics.

The sleek, contemporary design is available in Fab&Fix’s Hardex Chrome and Hardex Graphite finishes, which are supplied with a 10-year finish guarantee.

To help installers provide homeowners with the highest standards of security, TouchKey has been independently tested to BSI’s new Smart Residential Locking Device standard, which was developed in conjunction with ERA and combines the BSI Internet of Things (IoT) Kitemark with TS 621 for mechanical security with smart locking. It has also been awarded the Secured by Design (SBD) Secure Connected Device accreditation, which has been launched specifically for Internet of Things (IoT) connected products.

TouchKey is also supplied with a 10-year Mechanical Hardware Guarantee and two-year Smart Security Guarantee, so professionals can be confident that once they have finished the installation, they won’t have to return.

The solution is accompanied by complete fitting instructions and supported by a dedicated technical helpline, with ERA’s inhouse team of experts available to guide professionals through the installation process.

For further information on ERA’s new TouchKey solution, visit our dedicated TouchKey page.