Spoilt for Choice

Over 30 years ago, we launched the industry's first range of perfectly matching hardware, Fab&Fix.

We understand that when it comes to decorative hardware, attention to the finer details such as colour, style and finish is vital for creating a unified aesthetic. With over 200 items in our range, you can match our hardware to every application - from doors to details on PVCu windows, heritage timber windows and vertical sliding windows.

Fab&Fix hardware is elegantly designed to make a dynamic impact on your home's overall appearance whilst delivering state of the art functionality. Want to stand out from the crowd? With 5 unique styles and a diverse range of hardware to choose from. your home can be as unique as you want it to be.

At Fab&Fix we're passionate about delivering the perfect finish and offering the greatest choice of colour. Our palette currently includes 13 colours, all of which are well-considered, aesthetically perfect in finish and give a high-quality hardware appearance to any door.

Our wide range makes infusing style into your home easy.

Classic Range

A classic design for the modern home. Not overly fussy or fancy. Our Classic range offers neat, simple style to suit any type of home.

Heritage Range

Bring a sophisticated classy look to any period home. Ideal for big oak doors, period buildings and old cottages.

Forged Range

Developed to replicate the finish of traditional iron forged hardware with the benefits of state-of-the art manufacturing.

Architectural Range

A sleek contemporary hardware range. Ideal for adding atmospheric style and standing out from the crowd.

Stainless Range

For the ultra-modern home. Flat and rounded stainless steel bar handles with matching accessories for the perfect finish.

As one of the UK's leading window and door hardware manufacturers, we have an unrivalled reputation for high quality design and technical innovation.

Our hardware is manufactured to internationally recognised standards. Every product is quality checked during production, before shipping and again on arrival. So, you can be sure that every product is perfect, from how the hardware feels in your hand through to its functionality and finish - no bubbles. no ripples, not even the slightest blemish.

That's why we confidently stamp every box with our mark of quality.

Rest assured that our colours will always be consistent across every product style and finish. Our strict manufacturing and quality processes ensure a consistent finish every time and not just on a single production batch.

At Fab & Fix, we give the smallest details our full attention to ensure we deliver a perfect product to every door and window.

- Every product is packaged with the same attention to detail that we use during the manufacturing process.

- All parts are supplied with fixings and in separate chambers where applicable to ensure no scratching of parts during transit.

- There's nothing worse than a beautiful handle and different coloured screws. With Fab&Fix, all our screwheads coordinate with the hardware.

- We know that all doors are not the same, which is why our door handles are supplied with a wider backplate to suit cylinder guards.

- Care instructions are supplied with every product to ensure that the hardware is maintained in optimal condition.

- Supplied fully assembled so there's no need to fit springs or levers.

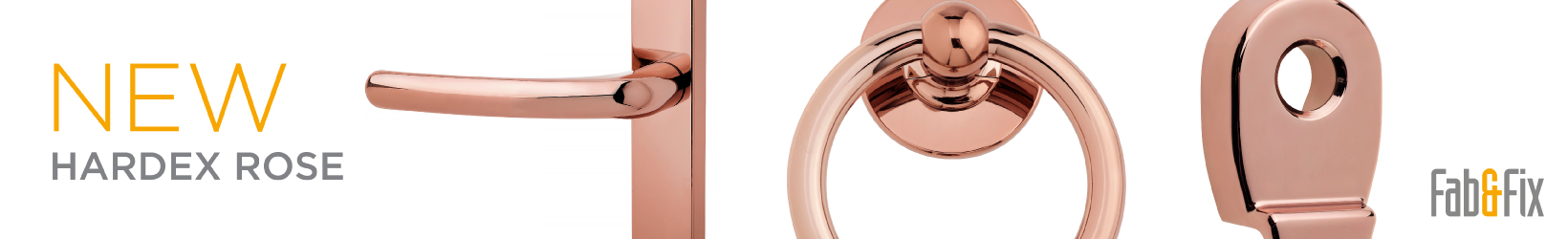

Each piece of hardware is engineered for enhanced strength and durability, whatever your style preference. The key to this enhancement is Hardex, an invisible skin that creates unmatchable resilience. Hardex finishes offer exceptional resilience and durability.

It all starts with the expertise of our design engineers and tool makers - only the most refined castings make the grade for a Hardex coat. Time is then of the essence, it takes over 24 hours to perfect a single handle. Meticulous preparation of the surface material is followed by a complex series of chemical baths, each submersion calculated to the second. Now the product is ready for Hardex to be applied before curing in extreme temperatures. It's a lot of effort but we hope you'll agree it's worth it.

We know that when a door or window looks great, it needs to stay that way, so it's imperative our products lead the way in anti-corrosion and performance standards.

The ultimate hardware requires the ultimate test, so we moved on from neutral salt spray testing (NSST) a long time ago as it isn't representative of real world conditions. Instead, we use far more rigorous prohesion testing to put Hardex through its paces. This combines an electrolyte spray sequence with drying cycles at high temperatures to concentrate salt deposits on the hardware.

Prohesion testing, which is designed to expose even the slightest of coating weaknesses, is the only method of corrosion testing to provide real peace of mind when it comes to ensuring long-lasting performance in the real world.

Hardex can sail through 1000 hours of this barrage, confirming it's the most durable finish on the market. However, there's still no replacement for the rigours of the field and Fab&Fix products have racked up plenty of test hours there too - the Fab&Fix brand is over 30 years old.